CNC Turning Part Manufacturer China: Quality and Precision at Its Best

In the realm of metal fabrication, the role of a cnc turning part manufacturer in China is pivotal. At DeepMould.net, we pride ourselves on our unwavering commitment to precision, quality, and innovation. Our extensive experience in the industry has established us as a leading player, catering to diverse sectors with top-tier manufacturing solutions.

The Importance of CNC Turning in Modern Manufacturing

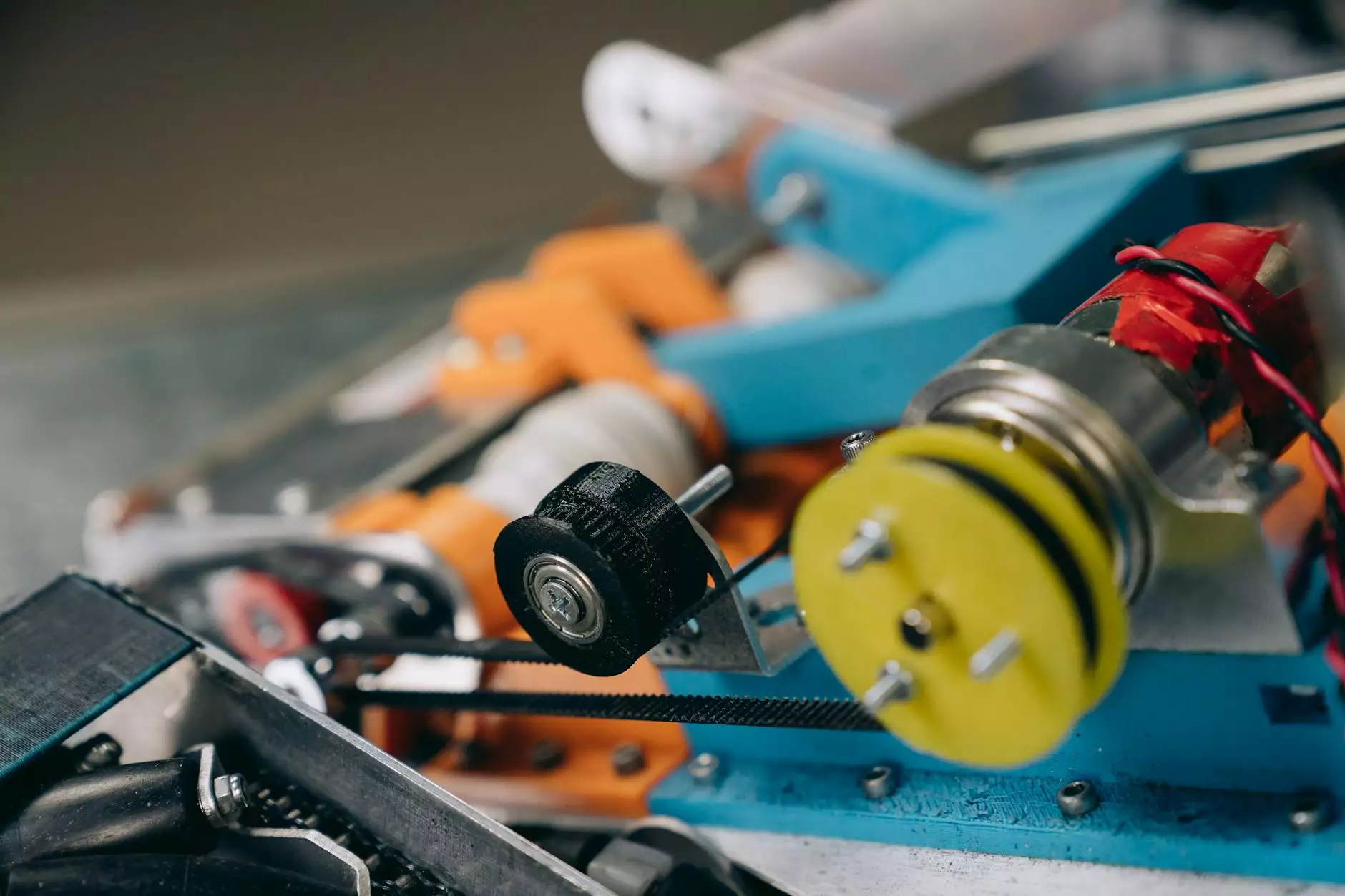

CNC turning is a crucial process in modern manufacturing, utilized to produce components with intricate designs and tight tolerances. By employing advanced CNC (Computer Numerical Control) technology, manufacturers can efficiently create parts that adhere to strict specifications. This level of precision is vital in industries such as automotive, aerospace, electronics, and medical devices.

- Increased Efficiency: CNC turning allows for high-speed production, significantly reducing lead times.

- Consistency: Automated processes ensure that each part is produced to the same high standards.

- Complex Designs: CNC technology can handle intricate designs that manual machining cannot achieve.

Why Choose DeepMould.net as Your CNC Turning Part Manufacturer?

When searching for a reliable cnc turning part manufacturer in China, several factors make DeepMould.net the optimal choice:

1. Advanced Technology and Equipment

We invest heavily in state-of-the-art CNC machinery and technology. Our CNC turning centers are equipped with the latest tools and software, enabling us to produce high-precision parts efficiently. Our commitment to innovation ensures that we stay ahead in the competitive manufacturing landscape.

2. Skilled Workforce

Our team consists of highly trained and experienced professionals who are passionate about delivering excellence. Each member is equipped with the skills necessary to oversee every aspect of the manufacturing process, ensuring that our products meet the highest quality standards.

3. Comprehensive Quality Control

At DeepMould.net, quality control is paramount. We implement rigorous testing at each stage of production, from the initial design phase through to the final product delivery. This approach allows us to identify and rectify potential issues early, thereby ensuring that only the best parts leave our facility.

4. Custom Solutions

Every project is unique, and we understand the necessity for tailored solutions. We work closely with our clients to design and manufacture customized CNC turning parts that meet their specific requirements. Our flexibility and willingness to adapt set us apart as a truly client-focused organization.

Our CNC Turning Services

DeepMould.net offers a wide range of CNC turning services designed to meet the needs of various industries:

1. Precision Machining

Our precision machining services focus on producing components with tight tolerances. Utilizing advanced CNC technology, we ensure that your parts are crafted to perfection, enhancing their performance in their intended applications.

2. Production in Various Materials

We are capable of machining parts from a variety of materials, including:

- Aluminum: Lightweight and highly machinable.

- Stainless Steel: Exceptional strength and corrosion resistance.

- Copper and Brass: Excellent conductivity and machinability.

- PVC and Other Plastics: Versatile options for unique applications.

3. Prototyping Services

Understanding the importance of prototyping, we offer rapid prototyping services that allow clients to visualize and test their designs before full-scale production. This process helps mitigate risks and ensures your final product aligns with your expectations.

Industries We Serve

DeepMould.net serves a wide range of industries, providing tailored solutions to meet their unique demands:

1. Automotive Industry

The automotive sector relies on precision-engineered components for enhanced performance and safety. Our CNC turning parts are used in various applications, including drive systems, engine components, and assembly parts.

2. Aerospace and Defense

In the aerospace and defense industries, quality and reliability are non-negotiable. Our parts meet stringent safety and regulatory standards, making them ideal for mission-critical applications.

3. Electronics

We supply machined components for electronic devices, including housings, connectors, and internal components. Our meticulous attention to detail ensures that each part functions flawlessly.

4. Medical Devices

Medical manufacturing requires precision and adherence to strict regulations. Our CNC turning services produce components for surgical instruments, implants, and other medical devices with the utmost care and quality.

Benefits of Partnering with a CNC Turning Part Manufacturer in China

Choosing the right cnc turning part manufacturer China can unlock numerous benefits for your business:

- Cost-Effectiveness: Manufacturers in China often provide competitive pricing without compromising quality, resulting in significant cost savings.

- Scalability: As your business grows, our capacity to scale production allows for seamless transitions into larger orders.

- Access to a Global Supply Chain: Partnering with a Chinese manufacturer gives you access to a vast supply chain network, streamlining logistics and delivery.

The Future of CNC Turning Manufacturing

The landscape of CNC turning is continually evolving, with advancements in technology paving the way for more efficient and sustainable practices. DeepMould.net is committed to staying at the forefront of these innovations, ensuring that we can continue to provide our clients with the highest quality products and services. Here are some trends shaping the future:

1. Automation and Smart Manufacturing

With the rise of automation and the Internet of Things (IoT), manufacturing processes are becoming increasingly interconnected. Our facilities are adopting smart technologies that enhance efficiency, reduce waste, and improve overall production quality.

2. Sustainable Practices

As environmental concerns grow, manufacturers are focusing on sustainability. We are implementing practices that reduce energy consumption and minimize waste, aligning our operations with global sustainability goals.

3. Advanced Materials

The development of new materials will revolutionize CNC machining, enabling the creation of more robust and lightweight parts. We are continually researching and incorporating new materials into our production processes to meet evolving industry demands.

Conclusion

In summary, choosing a cnc turning part manufacturer in China like DeepMould.net provides you with access to unmatched expertise, cutting-edge technology, and exceptional quality. Our dedication to customer satisfaction and commitment to excellence make us the premier choice for your CNC turning needs. Reach out to us today to discuss how we can partner in your success!