Unleashing the Power of 160i in Personal Protective Equipment and Welding Machines

Understanding the Concept of 160i

The term 160i may appear technical and abstract, yet it encapsulates the essence of innovation in various fields, particularly in the realm of industrial safety and welding technology. This article delves deep into the implications and applications of 160i, exploring how it intertwines with the categories of personal protective equipment (PPE) and welding machines, ultimately aiding professionals in their daily operations.

What is Personal Protective Equipment (PPE)?

Personal Protective Equipment refers to the gear worn by individuals to minimize exposure to hazards that could cause serious workplace injuries or illnesses. The significance of PPE cannot be overstated, as it serves as the first line of defense against potential threats such as chemicals, physical hazards, and airborne particles.

Key Categories of PPE

- Head Protection: Helmets and hard hats designed to shield the head from impact.

- Eye Protection: Safety glasses or goggles that prevent eye injuries from splashes, debris, or radiation.

- Hearing Protection: Earplugs and earmuffs to protect against noise-induced hearing loss.

- Respiratory Protection: Masks and respirators that filter out harmful substances in the air.

- Hand Protection: Gloves catering to various tasks to protect against cuts, abrasions, and exposure to chemicals.

The Role of 160i in Enhancing PPE Standards

The integration of 160i within the discourse of PPE represents a commitment to technological advancement. For instance, the materials used for PPE are constantly evolving, with the aim of providing better comfort, durability, and protection. The '160i' model can be seen as a benchmark for manufacturers to aspire to when developing new products.

Examples of Innovative PPE Products

Recent advancements in PPE have manifested in several noteworthy products:

- Smart Helmets: Equipped with augmented reality technologies, these helmets help workers navigate complex environments while keeping their hands free.

- Anti-Fog Safety Glasses: Enhanced with innovative coatings, these glasses maintain clarity in various environments, improving visibility and safety.

- Ergonomic Gloves: Designed to prioritize comfort without compromising protection, these gloves align with the principles of 160i by promoting user well-being.

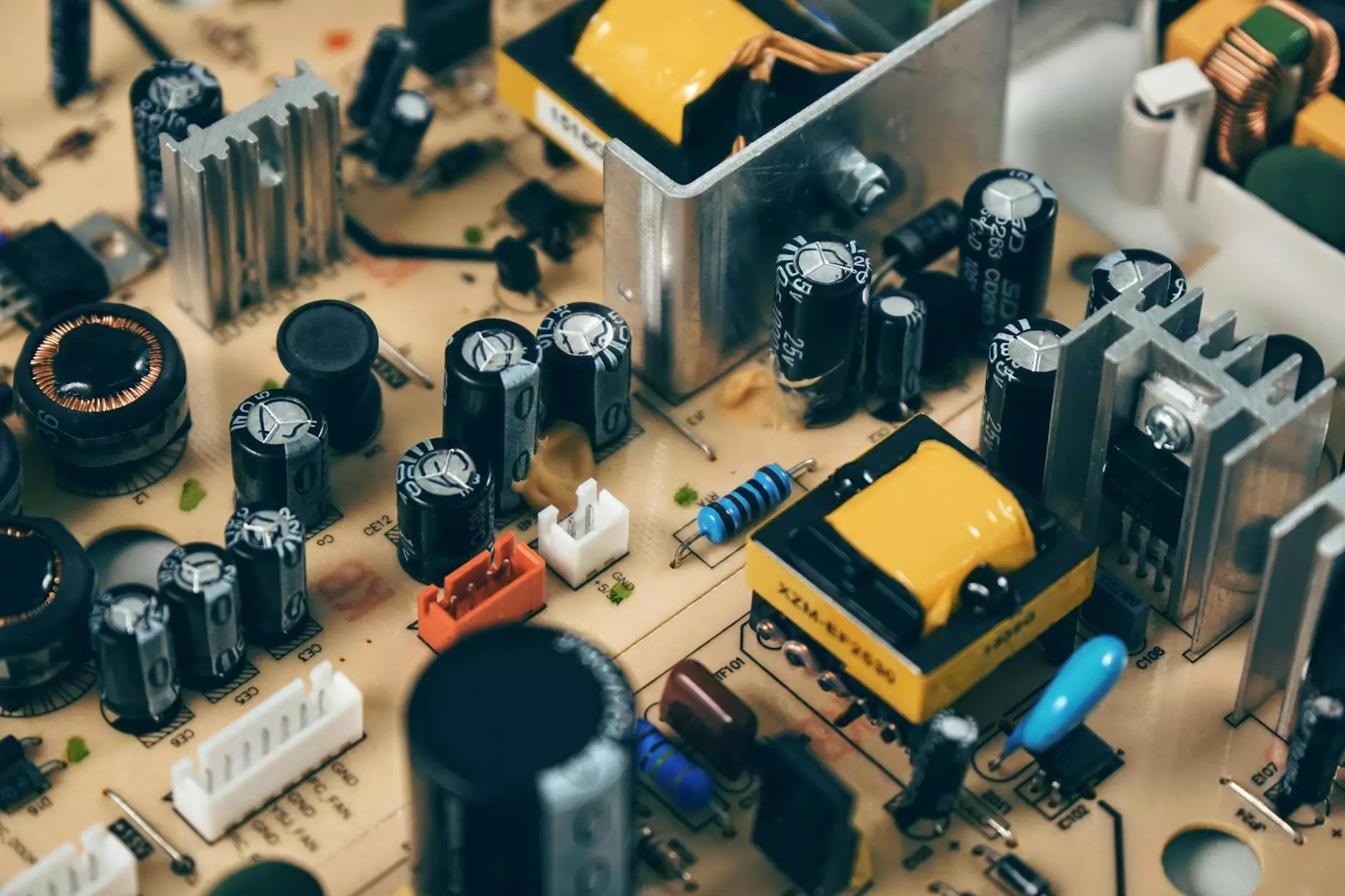

Welding Machines: An Overview

Welding machines are critical in various sectors, from manufacturing to construction. These machines enable the fusing of metals, creating strong bonds necessary for structural integrity. Understanding the technological parameters that influence welding performance is essential for achieving desired outcomes.

The Specifications of Modern Welding Machines

Modern welding machines come equipped with several technical specifications that align with industry standards, including:

- Welding Current: Machines are rated based on the maximum current they can supply, often described in terms of amperage.

- Voltage Range: A crucial factor for determining the type of work a machine can perform effectively.

- Duty Cycle: This refers to the ratio of the time a welding machine can operate to the time it requires to cool.

Connecting 160i to Welding Technology

The significance of 160i extends to the operational parameters of welding machines as well. For professionals in the industry, understanding the number 160 in conjunction with the variable 'i' could represent a specific setting or category within a welding context.

Choosing the Right Welding Machine

Selecting the right welding machine entails understanding its capabilities through detailed specifications. Key considerations include:

- Type of Welding: Whether it's MIG, TIG, or Stick welding, different machines cater to different techniques.

- Material Type: The compatibility with various metals such as aluminum, steel, or stainless steel.

- Portability: For on-site work, lightweight and compact machines often become a necessity.

The Importance of Safety in Welding

Welding poses various hazards, including exposure to harmful fumes, intense heat, and UV radiation. Therefore, the synergy between welding machines and PPE is crucial for ensuring a safe working environment.

Integrating PPE with Welding Processes

To optimize safety during welding operations, the following protective measures are essential:

- Welding Helmets: Equipped with auto-darkening features, these helmets protect the face and eyes during operations.

- Fire-Resistant Clothing: Protective gear designed with materials that resist burns and abrasions.

- Respiratory Equipment: Masks that filter out welding fumes and particulates, ensuring clean air for the worker.

Conclusion: The Future of 160i in Industrial Settings

As industries move forward, the relevance of 160i continues to grow, serving as a critical element in improving the quality and effectiveness of personal protective equipment and welding machines. For businesses such as tienda.gruporogu.com.mx, embracing the advancements around 160i can significantly enhance product offerings and ensure the safety of their customers. By focusing on innovative solutions, companies can not only comply with regulatory standards but also elevate their market position through enhanced consumer trust and satisfaction.

Explore More at tienda.gruporogu.com.mx

For a comprehensive selection of personal protective equipment and high-performance welding machines, visit tienda.gruporogu.com.mx. Stay ahead of the curve with products that prioritize safety, quality, and innovation in every facet of your work.